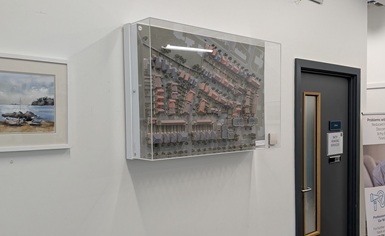

New lease of life for retired housing model.

After spending several years on the sidelines in the marketing suite of a large housing development in Bath, this “retired” sales model is back in the limelight after the client asked us to mount it on a wall in the development’s on-site community centre. We made the model back in 2017 as a marketing tool for the first phase of the development but once all the plots were sold the model was put to one side having served its purpose. Normally the model would be scrapped but the client decided to donate it to the community centre as an object of local interest. It wasn’t a big job but we were happy to get involved to give our model a new lease of life rather than end its days in a skip.

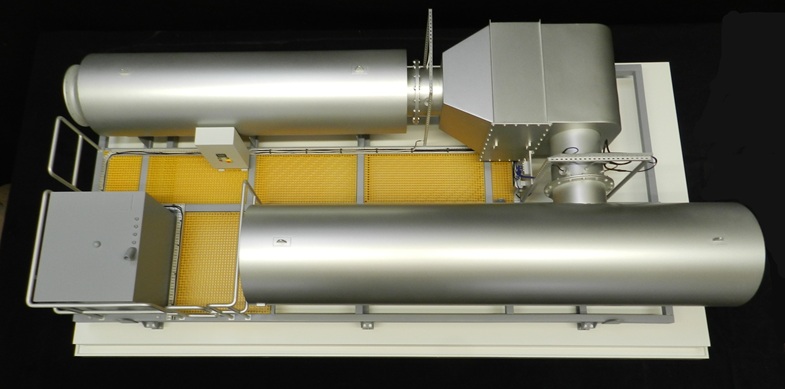

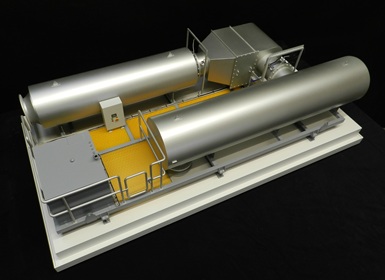

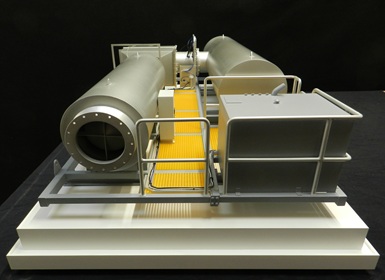

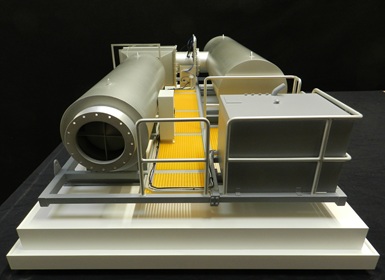

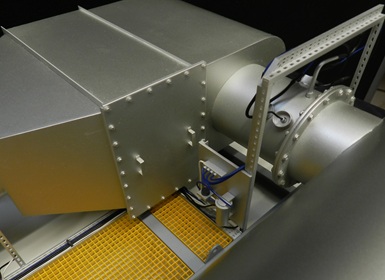

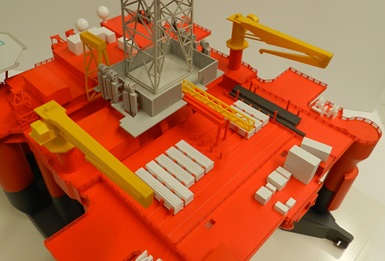

High-quality industrial model for exhibition event.

“I’ve got to say you’ve done a better job of building that, than we do the real thing. Honestly, the level of detail looks amazing!” This was the client’s reaction when we sent him photos of the model – and it wasn’t even fully finished at that point. They were equally impressed when they received the finished model, so much so that a director from their US and Canada based partner company got in touch shortly afterwards to order a second model to be shipped to their US offices. At 1:10 scale the model was just under 1m long and came with a custom-built Perspex cover.

Realistically detailed farm landscape for milk producer.

This is the second 1:32 scale model we’ve produced in the last 3 months – you can see the previous project if you click on the Recent Projects tab above and scroll back to October. As you can see from the photos, this scale allows us to show a high level of realistic detail in the landscaping and the structures. It’s also useful because a lot of detailed “off-the-shelf” items such as cows and vehicles can sourced on line. This model is actually a direct physical representation of a CGI model the company had produced for a previous marketing promotion.

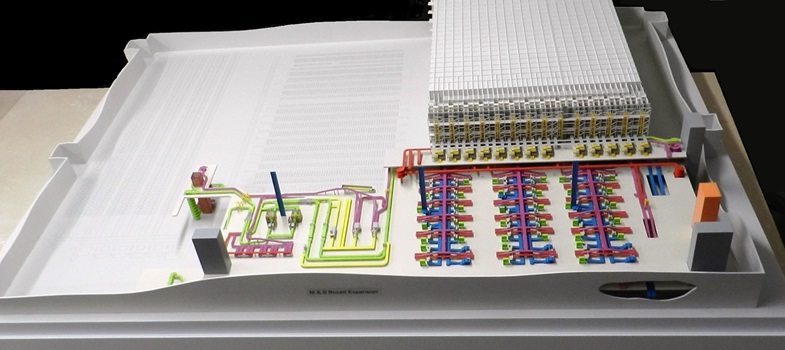

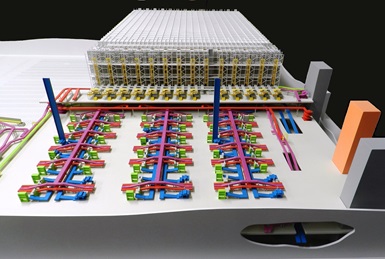

Our third warehouse model this year.

We seem to have found a niche for automated warehouse models as this is the third we’ve produced this year. They’re technically challenging projects due to the amount of small detail that needs to be modelled in the racking and conveyor belt systems but probably the most challenging aspect of these models is interpreting the extensive and highly detailed CAD files we have to work from. Fortunately we have a lot of experience producing complex industrial models of all descriptions so it’s become somewhat of a specialized field for us. If you’ve got a requirement for a model of machinery or an industrial installation of some sort, we’d welcome the opportunity to provide a quotation.

Three presentation models for drilling rig manufacturer.

At 1:400 scale these drilling rig models were only just over 200mm wide so were extremely small and fiddly to make. For example the handrails you can see in the close-up photos were less than 3mm tall. Because of the small scale the client said the models could be slightly simplified, which they are, but as you can see from the pics we still managed to show a high level of fine detail. When completed the three models were shipped to the client in Aberdeen, after which they were shipped on to their own clients as gifts.