Sectional demonstration model for new kennel design.

We were commissioned by the DogsTrust charity to produce a compact, portable model showing sectional views through their latest kennel design. The model needed to be detailed enough to illustrate the high-quality features of the design but small enough to be easily transportable. At 1:25 scale the model was less than 500mm long but you can see from the photos that we were able to show a high level of realistic detail. We also supplied the model with a sturdy, waterproof travel case with tailored internal foam lining.

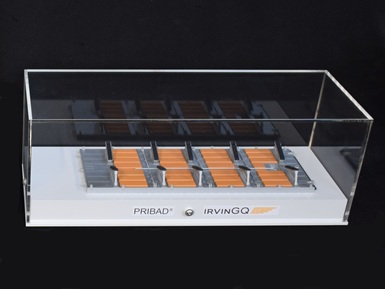

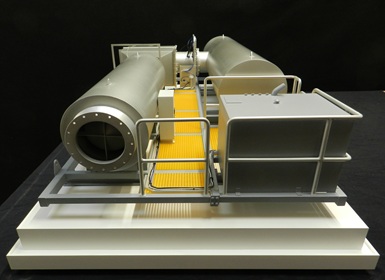

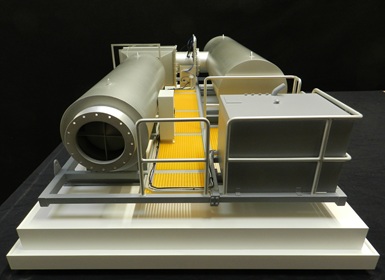

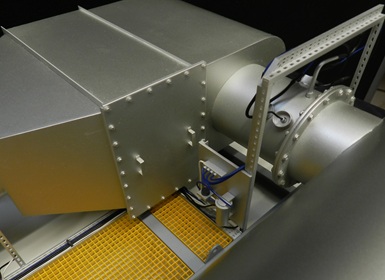

Small industrial model for exhibition events.

At 1:12 scale this compact industrial model was only 500mm long x 270mm high but showed all the detail the client required to demonstrate their product but crucially was also easily transportable, especially as we supplied it with a foam lined travel case. If you click on the first inset pic to enlarge it you can see a close up of the fine detail we are able to laser-engrave on the unit’s front panel.

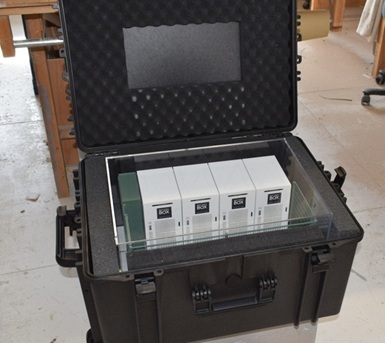

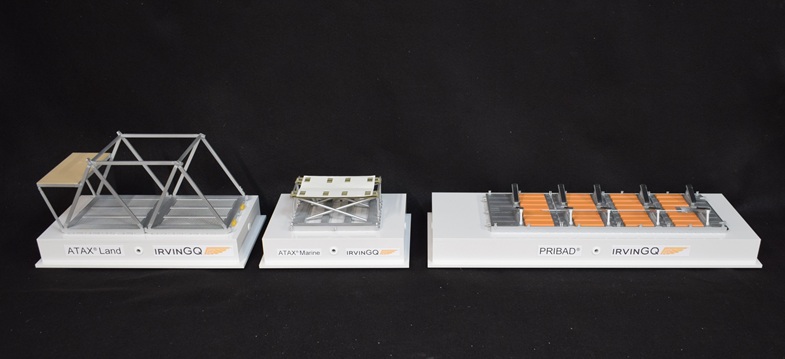

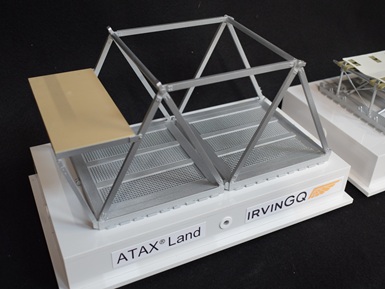

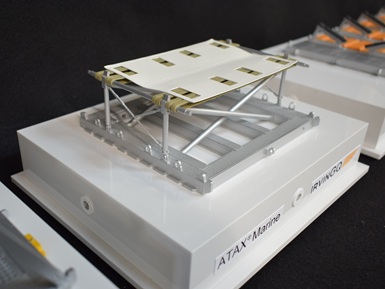

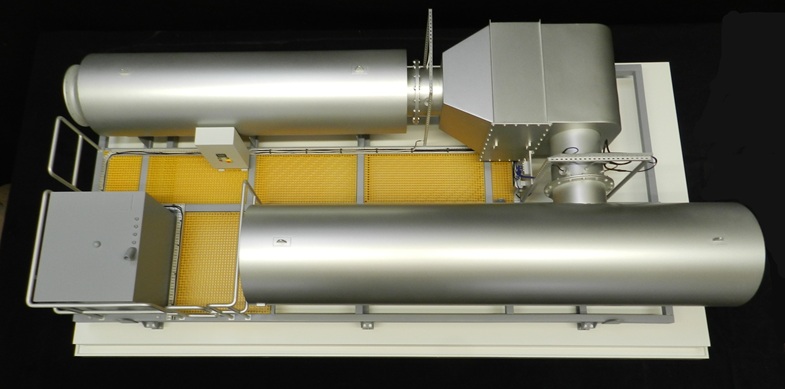

Three industrial models for an event in Rio.

A producer of specialized equipment for deploying military boats and vehicles via parachute into hard to reach areas, the client for this project asked us to create models of three of their core products for an event in Rio De Janeiro. At 1:20 scale the models were small enough to be easily transportable (the biggest was less than 500mm long) but still needed to show a high level of detail to demonstrate the characteristics of the product. We supplied all three models with custom-made Perspex covers and sturdy, waterproof travel cases with tailored foam interiors.

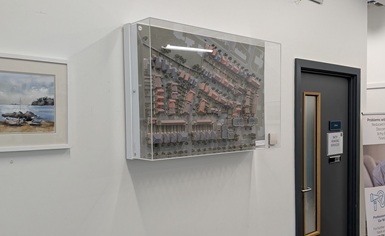

New lease of life for retired housing model.

After spending several years on the sidelines in the marketing suite of a large housing development in Bath, this “retired” sales model is back in the limelight after the client asked us to mount it on a wall in the development’s on-site community centre. We made the model back in 2017 as a marketing tool for the first phase of the development but once all the plots were sold the model was put to one side having served its purpose. Normally the model would be scrapped but the client decided to donate it to the community centre as an object of local interest. It wasn’t a big job but we were happy to get involved to give our model a new lease of life rather than end its days in a skip.

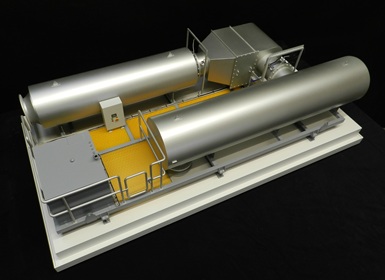

High-quality industrial model for exhibition event.

“I’ve got to say you’ve done a better job of building that, than we do the real thing. Honestly, the level of detail looks amazing!” This was the client’s reaction when we sent him photos of the model – and it wasn’t even fully finished at that point. They were equally impressed when they received the finished model, so much so that a director from their US and Canada based partner company got in touch shortly afterwards to order a second model to be shipped to their US offices. At 1:10 scale the model was just under 1m long and came with a custom-built Perspex cover.