Third project this year for South of England developer.

As with the previous post, this is one of three sales models we’ve produced this year for another of our regular clients who keep coming back to us for high quality sales models for their marketing suites. This model was at 1:150 scale which is the ideal scale option for smaller housing developments. Larger developments typically need to be at 1:200 scale or even 1:250 scale just to keep the model base to a manageable size. We were planning to post photos of all three projects this month but two of the almost completed models have gone on hold at the last minute due to some late design changes on site. It’s probably going to be a couple of months before the other two models can be fully completed but hopefully we’ll be able to post finished pics towards the end of this year.

Third sales model this year for major UK house builder.

This is the third sales model we’ve produced this year for one of the UK’s biggest housing developers. We’ve been supplying high quality sales models for their marketing suites for over 12 years and have another very large project for them booked in later this year. An important feature of this site was the sloping topography which had to be very precisely modelled so that the gardens with retaining walls and steps could be accurately represented. If you click on the right inset pic above you can see a close up example of these level changes.

2.2 metre high model of navigation buoy.

A company that produces and maintains navigation buoys around Britain’s coastlines asked us to produce this quarter scale model of one of their standard buoys for use at exhibition events. At 2.2m tall it had to be made in sections that could be packed in flight cases for shipping but that could be easily assembled on site. If you click on the main photo above you can see the full extent of the model. To add some extra visual interest we came up with the idea of mounting it on a clear Perspex tube to give the impression that it was floating.

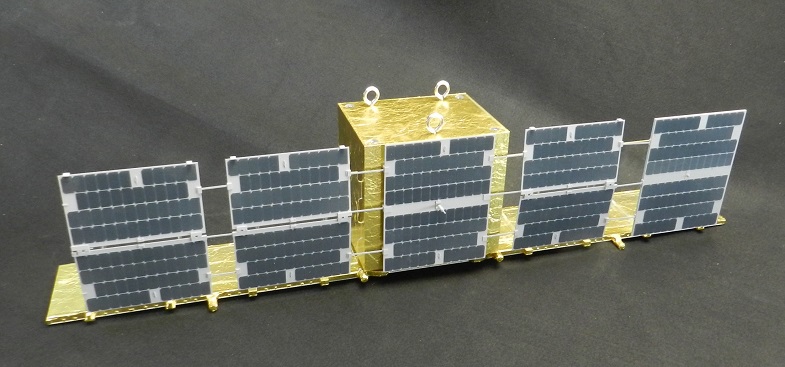

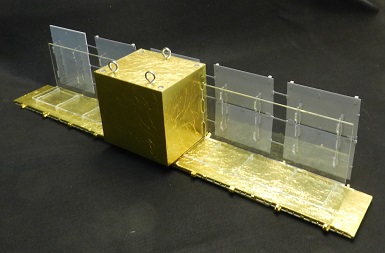

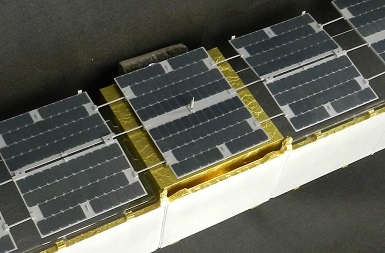

Two 1 metre long models for Finnish client.

We’ve produced many different satellite models over the years and recently completed two identical 1m long models for a client in Finland. The models have three removable hanging hooks because they’ve been designed to hang above an exhibition stand at an upcoming event. In one of the inset photos you can see how we used clear acrylic angle brackets to support the solar panels which weren’t strong enough to be self-supporting. The models were packed in two flight cases strapped to a pallet and arrived safe and sound in Finland last week.

Detailed models of three historic sites.

Back in 2021 we completed three models of megalithic tombs for a Heritage Centre in Northern Ireland (see Recent projects – May 2021) and they were so pleased with them they came back to us for three more models which we’ve just completed. As you can see from the photos above, they were three very diverse sites; a ruined church, a disused Water Mill and a landmark Cairn but hopefully we’ve captured the spirit and character of each of these three historic sites. All the models had to be interpreted from very limited information, chiefly consisting of images from reference books in conjunction with current site photos.