Interactive industrial model at 1:250 scale

When the guys at DHL (UK) spotted we’d made models for both UK Mail and Hermes they knew we were the right company to supply a high quality model of their brand new southern depot at Poyle, near Windsor. Like the UK Mail and Hermes models, this needed to be a “roof-off” view of the building showing the huge investment in sophisticated sorting machinery within the new depot. DHL actually went a step further and asked us to make the model interactive so that ten specific areas of the machinery could be illuminated individually at the touch of a button (you can see the buttons in the main pic above). The most difficult part of this project was deciphering the CAD info for the machinery and then modelling the complex industrial components to a slightly simplified but recognisable level. We then had to work out how to build in the LEDs so that only the relevant areas lit up. All in all, it was a very technically demanding brief but DHL were very clear what they wanted and we delivered!

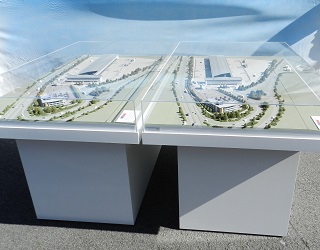

Two 1:400 scale models of parcel handling depot

UK Mail ordered two identical site models of their huge new facility at Ryton because they needed an overview model at either end of the site, one in the offices and one in the main warehouse building. Constructing two models at the same time enabled us to offer them a significant saving on the second unit. 1:400 scale is a good option for a site model because it keeps the base size down but still allows us to show a recognisable level of detail. We were even able to show a good representation of the parcel handling conveyors through the cut-away roof (click on the inset pic above to see the detail).

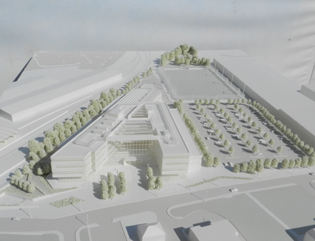

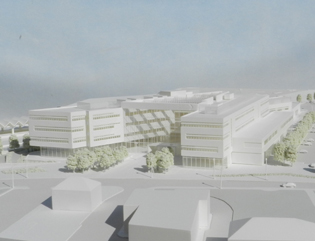

White styled model of proposed college buildings

This white styled model was used to illustrate a proposed design for a new college. The white styling was chosen deliberately so as not to be too specific about material finishes – these were to be finalized at a later date. 1:400 is quite a small scale but it is ideal for a site model because it allows us to show a wide overall area on a fairly compact base. And if you click on the images to enlarge them you’ll see that, despite the small scale, we can still show plenty of informative detail that invites close-up inspection and therefore engages the viewer. This was one of two models that formed an overall presentation. The second model (which will be the subject of my next post) was a larger scale sectional model focussing on the building’s main architectural feature, the central Atrium.

Small Scale Housing Model – Scale 1:500

This is an unusually small scale for a housing development marketing model – 1:200 scale or 1:250 is more typical for this type of project. This small scale was chosen due to limited space and a tight budget. But although this lacks the detail of the larger scales it does convey a clear easy to understand overview of this large spread out site. The grey blocks represent existing buildings that are not part of the development. If you click on the Enlarge Image feature on the picture, you’ll see that a surprising level of detail is shown (even though the house elevations are only about 14mm high) and we’ve even created accurate topography with stepped roof levels and sloping contours, etc.

Bangor University New Building – Scale 1:400

One of the main purposes of this model was to demonstrate how this major new building addresses a complex, steeply sloping site. It was also used to illustrate the scale and massing of the new development in relation to the existing university buildings and the surrounding townscape.