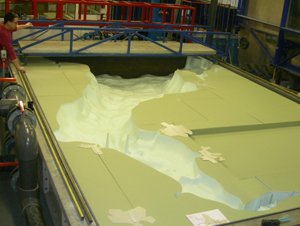

River Bed Model in Fibreglass – Horizontal Scale 1:125,000, Vertical Scale 1:125

Commissioned by Cardiff University’s Engineering Department, this 6 metre x 4 metre fibreglass model of the River Severn Estuary and Bristol Channel river beds was a very technically demanding job, not just because of the huge volume of complex data involved but also because of the sheer size of the project. Comprising several large sections that bolted together, it had to be an accurate representation of the riverbed contours (at an exaggerated vertical scale) because it was being used for physical experimentation in a major research program on tidal power generation.

How we made it

The first stage was to create a “mirrored” negative (upside down and back to front) version of the river bed contours all the way from Gloucester, down the Bristol Channel as far as the open sea. This comprised six major sections and several smaller, infill sections. These contours were made from laser cut acrylic layers supported on an MDF substructure, all fixed onto a structural base board with upstanding sidewalls. To construct the accurate depths and contours we had to create our own CAD masterplan using a combination of traditional Admiralty Charts, CAD contour maps, reams of numbers giving spot depths, and numerous sections through the river bed at key areas.

Once the basic structures of the moulds were built, the contours then had to be blended into a smooth continuous “land-form” using various filling techniques. At the same time great care had to be taken to ensure the contours matched perfectly across the joins between the sections. The contours then had to be sealed and “polished” to a fine finish so that the fiberglass forms would come away cleanly from the moulds once they had cured.

The final stage was to layer up resin and fiberglass matting into the moulds, starting with the “gelcoat” layer (which is in effect the top layer and is the visible finished colour) and then several more layers of resin and matting to build up the structural integrity. The fibreglass sections were then eased out of the moulds and flipped the right way up, ready to be joined together on to a structural sub-frame which supported them all at the right height. The image shows the sections just after they have come out of the moulds. They had been loosely assembled on the floor to check for fit.

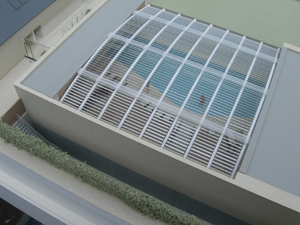

Detailed Internal Layout for Luxury Health Spa – Scale 1:100

Occasionally (not as often as we’d like) we get a real challenge in terms of authentic detailing of a model. This particular project was just such a case, its purpose being to show the internal layout and detailed finishes of a luxurious new health spa. The client wanted all the proposed internal fixtures and fittings accurately reproduced, from massage beds and gym equipment right down to floor colours and tile patterns. One of the close-up images features the finely detailed fins of the building’s sophisticated solar shading system.

Italian Villa Development – Scale 1:200

This model was used as a mobile marketing tool to help sell Italian holiday villas. The project involved very complicated land forming and intricately detailed buildings and had to be built to a very tight deadline whilst liaising with the Italian architects.

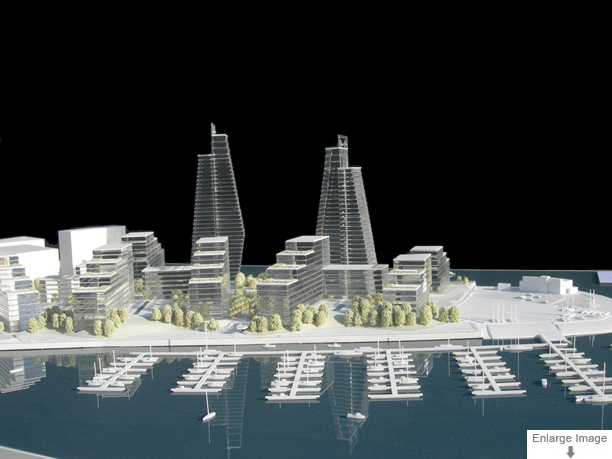

White/Perspex Concept Model – Scale 1:500

In contrast to the detailed school model, also shown on this page, this was a very simple model at a much smaller scale, designed to show the proposed massing and site layout for a large residential development.

White Styled School – Scale 1:200

A good example of a detailed white styled model, showing how informative this stylized architectural look can be. It’s a particularly useful approach when a model needs to be produced before final decisions have been made on colours and finishes of external materials.